In recent years, with the continuous increase of policies on the new energy industry, and the continuous fermentation of the event that Apple, Xiaomi and other technology giants entered the new energy vehicle market, the new energy industry has become more and more popular. Silver is widely used in the new energy industry because of its excellent characteristics. More and more newly increased photovoltaic installed capacity, the vast new energy vehicle market, and the seething "30 · 60" carbon peak, carbon neutral and dual carbon targets mean that the demand for silver may show a blowout upward trend. To sum up, the logic of making money for silver is particularly clear, driven by huge demand. So the topic of our article today is hard silver plating technology in silver plating.

Hard silver characteristics

Silver plating started in 1838, and the cyanide silver plating process proposed by the British has been used ever since. Silver plating is standard for most electroplating companies. Hard silver plating is one of the branches.

First, the concept of hardness is introduced. Hardness: the ability of a material to resist local hard objects pressing into its surface is called hardness. Hardness is not a simple physical concept, but a comprehensive index of mechanical properties such as elasticity, plasticity, strength and toughness of materials. The hardness unit used in this paper is Vickers hardness (HV).

Hard silver, as its name implies, is a kind of silver with high hardness. It is basically alloy based, but also uses intermediates to change its structure (AgSb, AgPd, AgPb) to increase the hardness of the silver coating. There are two important indicators for unqualified hard silver, one is its own hardness (which directly affects the service life), and the other is thermal attenuation (which affects the reliability). Hard silver products are widely used in charging posts of new energy vehicles and high-voltage and high current power supply equipment. Compared with ordinary silver plating, hard silver plating has better friction resistance and can increase the service life of connectors.

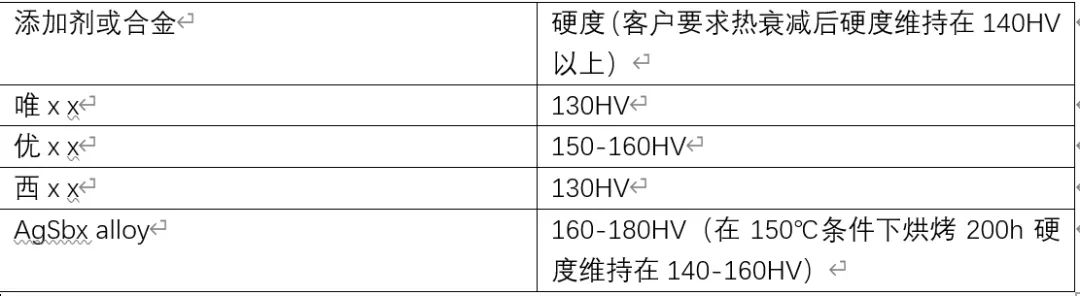

If you want to run an electric car, you need a charging pile. If you want the electric pile to pass, the hardness must be improved. Manufacturers of new energy vehicles have strict requirements on suppliers in terms of hardness and thermal attenuation. The hardness of hard silver is required to be between 160HV-180HV, and the hardness should still be above 140HV after the thermal attenuation test. Although most electroplating companies in the industry can reach 160HV, the hardness will drop to about 100HV after thermal attenuation test. After years of research, Edison's scientific research team finally solved the technical problem of large thermal attenuation value of hard silver. Edison's hard silver products have a small thermal decay index, and only decay 20HV after being baked at 150 ℃ for 200 hours. This means that the hardness of hard silver can always be maintained above 140HV (see the following table for specific results). All indicators of Edison's hard silver products can meet the needs of middle and high-end customers.

(Results of hard silver tests conducted by Aidisheng with different schemes)

The rise of China's manufacturing industry requires a large number of enterprising Chinese enterprises to strive for it! Aidisheng electroplating will surely become the preferred supplier of functional electroplating in the world!